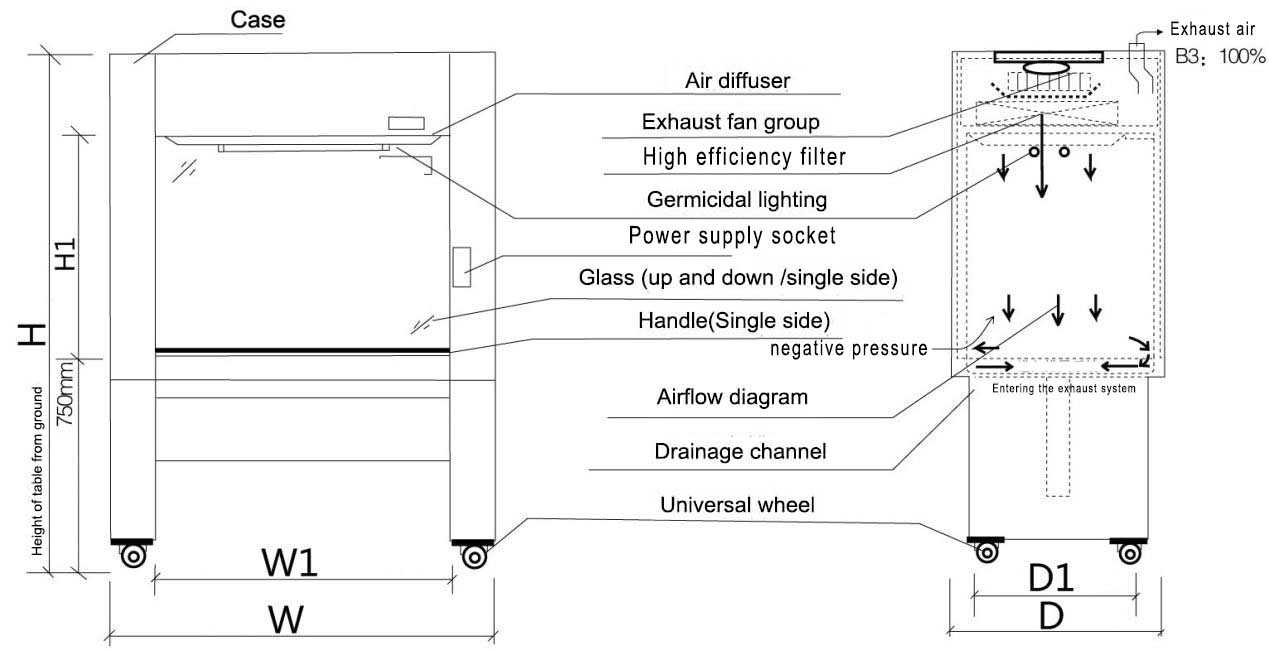

Schematic diagram of full exhaust type structure

Structure

Features

| Model Parameter | DRK-1000IIB2 | DRK-1300IIB2 | DRK-1600IIB2 | BHC-1300IIA/B3 | ||

| 10° tilt angle of front window | Vertical face | |||||

| Exhaust way | 100%Efflux | |||||

| Cleanliness | 100@≥0.5μm(USA209E) | |||||

| Number of colonies | ≤0.5Pcs/dish·hour(Φ90㎜Culture plate) | |||||

| average wind speed | Inside the door | 0.38±0.025m/s | ||||

| intermediate | 0.26±0.025m/s | |||||

| Inside | 0.27±0.025m/s | |||||

| Front suction wind speed | 0.55m±0.025m/s(100%Efflux) | |||||

| Noise | ≤62dB(A) | |||||

| Power Supply | ACSingle phase220V/50Hz | |||||

| Vibration half peak | ≤3μm | ≤5μm | ||||

| Maximum power consumption | 800W | 1000W | ||||

| Weight | 150kg | 200kg | 250kg | 300kg | ||

| Work area size | W1×D1×H1 | 1000×635×620 | 1300×635×620 | 1600×635×620 | 1340×620×590 | |

| Dimensions | W×D×H | 1195×785×1950 | 1495×785×1950 | 1795×785×1950 | 1540×785×1950 | |

| High efficiency filter specification and quantity | 955×554×50×① | 1295×554×50×① | 1595×554×50×① | 1335×600×50×① | ||

| Specification and quantity of fluorescent lamp/ultraviolet lamp | 20W×①/20W×① | 30W×①/30W×① | 30W×①/30W×① | 30W×①/30W×① | ||

1. Comply with the requirements of China SFDA YY0569 standard and American NSF/ANS|49 standard for Class II biological safety cabinet 2. The box body is made of steel and wood structure, and the whole machine is equipped with movable casters, which is convenient for transportation and installation

1. Comply with the requirements of China SFDA YY0569 standard and American NSF/ANS|49 standard for Class II biological safety cabinet 2. The box body is made of steel and wood structure, and the whole machine is equipped with movable casters, which is convenient for transportation and installation 3. DRK series 10° tilt design, more ergonomic

4. Vertical flow negative pressure model, 100% of the air can be discharged indoors or connected to the exhaust system after being filtered 5. Safety interlock between lighting and sterilization system 6. HEPA high efficiency filter, the filtration efficiency of 0.3μm dust particles can reach more than 99.99% 7.Digital display LCD control interface, fast, medium and slow speed, more humane design 8. The working area is made of SUS304 brushed stainless steel, which is strong, durable, easy to clean and anti-corrosion 9. Standard configuration of 160mm diameter, 1 meter long exhaust pipe and elbow 10. One five-hole socket in the work areaThe location of the biological clean safety cabinet should be in a clean working room (preferably placed in a primary clean room with a level of 100,000 or 300,000), plug in the power source, and turn it on according to the function shown on the control panel. , Before starting up, the working area and shell of the biological clean safety cabinet should be carefully cleaned to remove surface dust. Normal operation and use can be carried out ten minutes after starting up.

Technical Parameter

Maintain

The biological safety cabinet is composed of several major components such as a cabinet, a fan, a high-efficiency filter, and an operation switch. The box body is made of high-quality materials, the surface is sprayed with plastic treatment, and the work surface is made of stainless steel. The purification unit adopts a fan system with adjustable air volume. By adjusting the working conditions of the fan, the average wind speed in the clean working area can be kept within the rated range, and the service life of the high-efficiency filter can be effectively extended.

Working Principle

General faults, causes, and troubleshooting methods

1. Generally, when the working voltage of the fan is adjusted to the highest point after the eighteenth is used, when the ideal wind speed is still not reached, it means that the high-efficiency filter has too much dust (the filter hole on the filter material has been basically blocked, and it should be updated in time) , Generally, the service life of high efficiency air filter is 18 months.

2. When replacing the high-efficiency air filter, pay attention to the correctness of the model, specification and size (configured by the original manufacturer), follow the arrow wind direction device, and pay attention to the surrounding seal of the filter, and there is absolutely no leakage.

| Failure phenomenon | The reason | Elimination method |

| The main power switch fails to close, and it automatically trips | 1. The fan is stuck and the motor is blocked, or there is a short circuit in the circuit | 1. Adjust the position of the fan shaft, or replace the impeller and bearing, and check whether the circuit is in good condition. 2. Check the insulation resistance of the circuit and components to the shell point by point according to the wiring diagram, and repair the insulation failure. |

| Low wind speed | 1. The high efficiency filter fails. | 1. Replace the high efficiency filter. |

| Fan does not turn | 1. The contactor does not work. 2. The blower power fuse has been blown. | 1. Check whether the contactor circuit is normal. 2. Replace the fuse. |

| Fluorescent light does not light up | 1. The lamp or relay is damaged. 2. The lamp power fuse has been blown. | 1. Replace the lamp or relay. 2. Replace the fuse. |

Install and use

Air is sucked in from the top of the box, and driven by the air blower, the air is sent to the static pressure box, filtered by a high-efficiency filter, and sent to the safe cabinet operation area. The downdraft is mixed with the air sucked in from the opening surface of the safety cabinet operation area, and then is discharged to the outdoors after being filtered by the exhaust filter and driven by the central exhaust system or the external exhaust fan through the external exhaust duct.