| External temperature | 0 ° C ~ 35 ° C |

| External pressure | standard atmospheric pressure |

| Relative humidity | ≤90%RH |

| Power supply | 220V ± 10% |

| studio size (mm) | 400 × 400 × 500 (80L) |

| ozone concentration | 25 ~ 1000pphm. (adjustable) |

| Ozone concentration deviation | ≤5% |

| laboratory temperature | RT + 10 ° C ~ 60 ° C |

| temperature fluctuation | ± 0.5 ° C |

| uniformity | ± 2 ° C |

| test gas flow | 20 ~ 80L / min |

| test device | static |

| sample rack speed | 360 rotating sample holder (speed 1 revolutions per minute) |

| ozone source | ozone generator (using voltage silent discharge tube to produce ozone) |

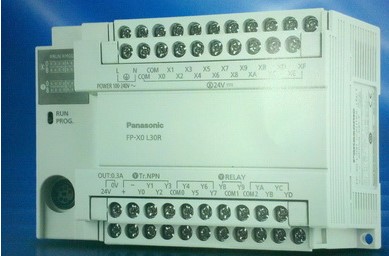

| Sensor | UK imported ozone concentration sensor for precise control the controller uses the Japanese Panasonic PLC |

| 14. The equipment meets the standard | GB/T7762-2003 ASTM1149 ISO1431 GB/T 13641-92 HG/T 2869-97 |

(Main Controller Screen)

(Dynamic)

(Static state)

Introduction to the Overall Structure 1. The outer shell of the whole box is made of 1.2mm cold plate by electrostatic spraying with NC machine tool. The color is light camel. The wall material of the test room is SUS304 high-grade corrosion-resistant stainless steel plate, which has reasonable structure design, excellent manufacturing technology and beautiful appearance. According to the temperature requirement of the laboratory, the thickness of insulation layer is designed as follows: 100mm. 2. The insulation material between the inner box and the outer box is superfine glass fiber insulation cotton, which plays a good role in cold or hot insulation. 3. Imported sealing material and unique silica gel sealing structure are used between door and door frame, and the sealing performance is good. 4. Test box door structure: single door. Door locks, hinges and other hardware accessories for Japan's "TAKEN" original imported accessories. 5. Hollow glass observation window with conductive film is used in the door of the box. The size of the observation window is 200 *300 mm. Observe the glass with an electronic heater to prevent condensation and defrosting. 6 heaters: stainless steel 316LI fin type special electric heat pipe; 7. Four universal runners are equipped to facilitate box movement. Control System 1. The original imported Panasonic PLC, ozone concentration control instrument and imported ozone concentration sensor from Britain can accurately detect and control ozone concentration, and the deviation of ozone concentration can be controlled to less than 5% (the national standard requirement is less than 10%). 2. Temperature Controller: Panasonic PLC, man-machine touch screen using Weinview of Taiwan Willenton; 3. Temperature Sensor: PT100 Platinum Resistance Temperature Tester; 4. Control mode: heat balance temperature regulation mode; 5. Electrical control components: using "Schneider" and "Omron" components to better control temperature refer to the picture.| Name: | Brand and model: | Place of Origin: |

| Case housing | Electrostatic Spraying of 1.2mm High Quality Steel Plate | Shanghai |

| Chassis | Stainless Steel Plate on 6# Channel Steel Surface | Shanghai |

| Internal bladder | 1mm SUS304 stainless steel wire drawing board | Shanghai |

| Thermal insulation material | Ultrafine Glass Fiber Thermal Insulation Cotton | Shanghai |

| AC contactor | Schneider | France |

| Solid state relay | Kang Yu | Wuxi |

| electromagnetic relay | OMRON | Japan |

| Controller | Panasonic PLC | Japan |

| Hollow anti-fogging steel observation window | Pei Xin | Guangdong |

| Fin electric heat pipe | Rainbow | Shanghai |

| PT100 Temperature Sensor | German "tecsis" | Germany |

| Centrifugal motor | Su Heng | Changzhou |

| Ozone detection probe | ZP-3290 | Britain |

| Ozone Generator | AOKANG | Zhejiang |

| Touch screen | Warren Tong | Taiwan |