Product Structure: 1. The unique balance temperature adjustment method enables the equipment to have stable and balanced heating and humidification capabilities, and can perform high-precision and high-stability constant temperature control. 2. The studio is made of SUS304 stainless steel plate, and the sample shelf is also made of stainless steel, which is corrosion-resistant and easy to clean. 3. Heater: stainless steel finned heat sink. 4. Humidifier: UL electric heater 5. The temperature control part of the equipment adopts an intelligent control instrument, PID self-tuning, high precision and high stability to ensure precise control of the equipment. 6. The equipment has over-temperature protection, voice prompts and timing functions. When the timing ends or alarms, the power supply will be automatically cut off to stop the equipment to ensure the safety of the equipment and the person. 7. Sample rack: all stainless steel material. 8. Safety protection measures: over-temperature protectionpower leakage circuit breaker Precautions for Use: Precautions for Using New Machine 1. Before using the equipment for the first time, please open the box baffle to check if any components are loose or fall off during transportation. 2. When running a new device for the first time, there may be a slight peculiar smell. Precautions before equipment operation 1. Please confirm whether the equipment is reliably grounded. 2. Before the impregnation test, it must be dripped out of the test box and then placed in it. 3. Please install an external protection mechanism and supply system power according to the product nameplate requirements; 4. It is absolutely forbidden to test explosive, flammable and highly corrosive substances. 5. The water tank must be filled with water before it can be turned on. Precautions for equipment operation 1. When the equipment is running, please do not open the door or put your hands into the test box, otherwise it may cause the following adverse consequences. A: The inside of the test chamber still maintains a high temperature, which is likely to cause burns. B: UV light may burn the eyes. 2. When operating the instrument, please do not change the set parameter value at will, so as not to affect the control accuracy of the equipment. 3. Pay attention to the test water level and make up water in time. 4. If the laboratory has abnormal conditions or burnt smell, stop using it and check immediately. 5. When picking and placing items during the test, heat-resistant gloves or picking tools must be worn to prevent injury and the time should be as short as possible. 6. When the equipment is running, do not open the electrical control box to prevent dust from entering or electric shock accidents. 7. During the test, the temperature and humidity should be kept constant before turning on the UV light switch. 8. When testing, first make sure to turn on the blower switch. Remark: 1. Within the adjustable temperature range of the test equipment, generally select the representative temperature nominal value specified in the GB/2423.24 standard: normal temperature: 25°C, high temperature: 40, 55°C. 2. Under different humidity conditions, the photochemical degradation effects of various materials, coatings and plastics are very different, and their requirements for humidity conditions are different from each other, so the specific humidity conditions are clearly defined by relevant regulations. For example, it is stipulated that the first 4 hours of each cycle of test procedure B shall be executed under damp and heat conditions (temperature 40℃±2℃, relative humidity 93%±3%). Test procedure B: 24h is a cycle, 20h irradiation, 4h stop, test according to the required number of repetitions (this procedure gives a total radiation amount of 22.4 kWh per square meter per day and night. This procedure is mainly used to assess solar radiation Degradation effect) Note: Information changed due to technological progress will be not noticed. Please take actual product as standard.

Product Structure: 1. The unique balance temperature adjustment method enables the equipment to have stable and balanced heating and humidification capabilities, and can perform high-precision and high-stability constant temperature control. 2. The studio is made of SUS304 stainless steel plate, and the sample shelf is also made of stainless steel, which is corrosion-resistant and easy to clean. 3. Heater: stainless steel finned heat sink. 4. Humidifier: UL electric heater 5. The temperature control part of the equipment adopts an intelligent control instrument, PID self-tuning, high precision and high stability to ensure precise control of the equipment. 6. The equipment has over-temperature protection, voice prompts and timing functions. When the timing ends or alarms, the power supply will be automatically cut off to stop the equipment to ensure the safety of the equipment and the person. 7. Sample rack: all stainless steel material. 8. Safety protection measures: over-temperature protectionpower leakage circuit breaker Precautions for Use: Precautions for Using New Machine 1. Before using the equipment for the first time, please open the box baffle to check if any components are loose or fall off during transportation. 2. When running a new device for the first time, there may be a slight peculiar smell. Precautions before equipment operation 1. Please confirm whether the equipment is reliably grounded. 2. Before the impregnation test, it must be dripped out of the test box and then placed in it. 3. Please install an external protection mechanism and supply system power according to the product nameplate requirements; 4. It is absolutely forbidden to test explosive, flammable and highly corrosive substances. 5. The water tank must be filled with water before it can be turned on. Precautions for equipment operation 1. When the equipment is running, please do not open the door or put your hands into the test box, otherwise it may cause the following adverse consequences. A: The inside of the test chamber still maintains a high temperature, which is likely to cause burns. B: UV light may burn the eyes. 2. When operating the instrument, please do not change the set parameter value at will, so as not to affect the control accuracy of the equipment. 3. Pay attention to the test water level and make up water in time. 4. If the laboratory has abnormal conditions or burnt smell, stop using it and check immediately. 5. When picking and placing items during the test, heat-resistant gloves or picking tools must be worn to prevent injury and the time should be as short as possible. 6. When the equipment is running, do not open the electrical control box to prevent dust from entering or electric shock accidents. 7. During the test, the temperature and humidity should be kept constant before turning on the UV light switch. 8. When testing, first make sure to turn on the blower switch. Remark: 1. Within the adjustable temperature range of the test equipment, generally select the representative temperature nominal value specified in the GB/2423.24 standard: normal temperature: 25°C, high temperature: 40, 55°C. 2. Under different humidity conditions, the photochemical degradation effects of various materials, coatings and plastics are very different, and their requirements for humidity conditions are different from each other, so the specific humidity conditions are clearly defined by relevant regulations. For example, it is stipulated that the first 4 hours of each cycle of test procedure B shall be executed under damp and heat conditions (temperature 40℃±2℃, relative humidity 93%±3%). Test procedure B: 24h is a cycle, 20h irradiation, 4h stop, test according to the required number of repetitions (this procedure gives a total radiation amount of 22.4 kWh per square meter per day and night. This procedure is mainly used to assess solar radiation Degradation effect) Note: Information changed due to technological progress will be not noticed. Please take actual product as standard. DRK645 UV Lamp Weather Resistance Testing Box

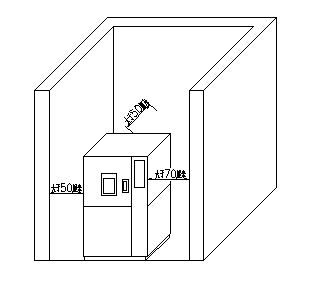

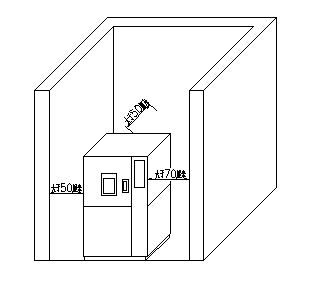

DRK645 UV lamp weather resistance testing box is to simulate UV radiation, used to determine the impact of UV radiation on equipment and components (especially the changes in the electrical and mechanical properties of the product).

Products Details

Product Structure: 1. The unique balance temperature adjustment method enables the equipment to have stable and balanced heating and humidification capabilities, and can perform high-precision and high-stability constant temperature control. 2. The studio is made of SUS304 stainless steel plate, and the sample shelf is also made of stainless steel, which is corrosion-resistant and easy to clean. 3. Heater: stainless steel finned heat sink. 4. Humidifier: UL electric heater 5. The temperature control part of the equipment adopts an intelligent control instrument, PID self-tuning, high precision and high stability to ensure precise control of the equipment. 6. The equipment has over-temperature protection, voice prompts and timing functions. When the timing ends or alarms, the power supply will be automatically cut off to stop the equipment to ensure the safety of the equipment and the person. 7. Sample rack: all stainless steel material. 8. Safety protection measures: over-temperature protectionpower leakage circuit breaker Precautions for Use: Precautions for Using New Machine 1. Before using the equipment for the first time, please open the box baffle to check if any components are loose or fall off during transportation. 2. When running a new device for the first time, there may be a slight peculiar smell. Precautions before equipment operation 1. Please confirm whether the equipment is reliably grounded. 2. Before the impregnation test, it must be dripped out of the test box and then placed in it. 3. Please install an external protection mechanism and supply system power according to the product nameplate requirements; 4. It is absolutely forbidden to test explosive, flammable and highly corrosive substances. 5. The water tank must be filled with water before it can be turned on. Precautions for equipment operation 1. When the equipment is running, please do not open the door or put your hands into the test box, otherwise it may cause the following adverse consequences. A: The inside of the test chamber still maintains a high temperature, which is likely to cause burns. B: UV light may burn the eyes. 2. When operating the instrument, please do not change the set parameter value at will, so as not to affect the control accuracy of the equipment. 3. Pay attention to the test water level and make up water in time. 4. If the laboratory has abnormal conditions or burnt smell, stop using it and check immediately. 5. When picking and placing items during the test, heat-resistant gloves or picking tools must be worn to prevent injury and the time should be as short as possible. 6. When the equipment is running, do not open the electrical control box to prevent dust from entering or electric shock accidents. 7. During the test, the temperature and humidity should be kept constant before turning on the UV light switch. 8. When testing, first make sure to turn on the blower switch. Remark: 1. Within the adjustable temperature range of the test equipment, generally select the representative temperature nominal value specified in the GB/2423.24 standard: normal temperature: 25°C, high temperature: 40, 55°C. 2. Under different humidity conditions, the photochemical degradation effects of various materials, coatings and plastics are very different, and their requirements for humidity conditions are different from each other, so the specific humidity conditions are clearly defined by relevant regulations. For example, it is stipulated that the first 4 hours of each cycle of test procedure B shall be executed under damp and heat conditions (temperature 40℃±2℃, relative humidity 93%±3%). Test procedure B: 24h is a cycle, 20h irradiation, 4h stop, test according to the required number of repetitions (this procedure gives a total radiation amount of 22.4 kWh per square meter per day and night. This procedure is mainly used to assess solar radiation Degradation effect) Note: Information changed due to technological progress will be not noticed. Please take actual product as standard.

Product Structure: 1. The unique balance temperature adjustment method enables the equipment to have stable and balanced heating and humidification capabilities, and can perform high-precision and high-stability constant temperature control. 2. The studio is made of SUS304 stainless steel plate, and the sample shelf is also made of stainless steel, which is corrosion-resistant and easy to clean. 3. Heater: stainless steel finned heat sink. 4. Humidifier: UL electric heater 5. The temperature control part of the equipment adopts an intelligent control instrument, PID self-tuning, high precision and high stability to ensure precise control of the equipment. 6. The equipment has over-temperature protection, voice prompts and timing functions. When the timing ends or alarms, the power supply will be automatically cut off to stop the equipment to ensure the safety of the equipment and the person. 7. Sample rack: all stainless steel material. 8. Safety protection measures: over-temperature protectionpower leakage circuit breaker Precautions for Use: Precautions for Using New Machine 1. Before using the equipment for the first time, please open the box baffle to check if any components are loose or fall off during transportation. 2. When running a new device for the first time, there may be a slight peculiar smell. Precautions before equipment operation 1. Please confirm whether the equipment is reliably grounded. 2. Before the impregnation test, it must be dripped out of the test box and then placed in it. 3. Please install an external protection mechanism and supply system power according to the product nameplate requirements; 4. It is absolutely forbidden to test explosive, flammable and highly corrosive substances. 5. The water tank must be filled with water before it can be turned on. Precautions for equipment operation 1. When the equipment is running, please do not open the door or put your hands into the test box, otherwise it may cause the following adverse consequences. A: The inside of the test chamber still maintains a high temperature, which is likely to cause burns. B: UV light may burn the eyes. 2. When operating the instrument, please do not change the set parameter value at will, so as not to affect the control accuracy of the equipment. 3. Pay attention to the test water level and make up water in time. 4. If the laboratory has abnormal conditions or burnt smell, stop using it and check immediately. 5. When picking and placing items during the test, heat-resistant gloves or picking tools must be worn to prevent injury and the time should be as short as possible. 6. When the equipment is running, do not open the electrical control box to prevent dust from entering or electric shock accidents. 7. During the test, the temperature and humidity should be kept constant before turning on the UV light switch. 8. When testing, first make sure to turn on the blower switch. Remark: 1. Within the adjustable temperature range of the test equipment, generally select the representative temperature nominal value specified in the GB/2423.24 standard: normal temperature: 25°C, high temperature: 40, 55°C. 2. Under different humidity conditions, the photochemical degradation effects of various materials, coatings and plastics are very different, and their requirements for humidity conditions are different from each other, so the specific humidity conditions are clearly defined by relevant regulations. For example, it is stipulated that the first 4 hours of each cycle of test procedure B shall be executed under damp and heat conditions (temperature 40℃±2℃, relative humidity 93%±3%). Test procedure B: 24h is a cycle, 20h irradiation, 4h stop, test according to the required number of repetitions (this procedure gives a total radiation amount of 22.4 kWh per square meter per day and night. This procedure is mainly used to assess solar radiation Degradation effect) Note: Information changed due to technological progress will be not noticed. Please take actual product as standard. Featured Products

-

D0001 Dry Aging Seat

-

DRK-FX-D302B Cooling-Water-Free Kjeltec Azotometer

-

DRK8681 Gloss Meter

-

DRK101SD Electronic Tensile Testing Machine

-

DRK8092 Stress Meter

-

F0009 Flammability Tester

-

DRK100 Simulation Transport Vibrating Table

-

DRK321B-II Surface Resistivity Tester

-

DRK6601-2000 Turbidity Meter

-

DRK8096 Cone Penetration Meter

Contact us

Please feel free to give your inquiry in the form below We will reply you in 24 hours